-

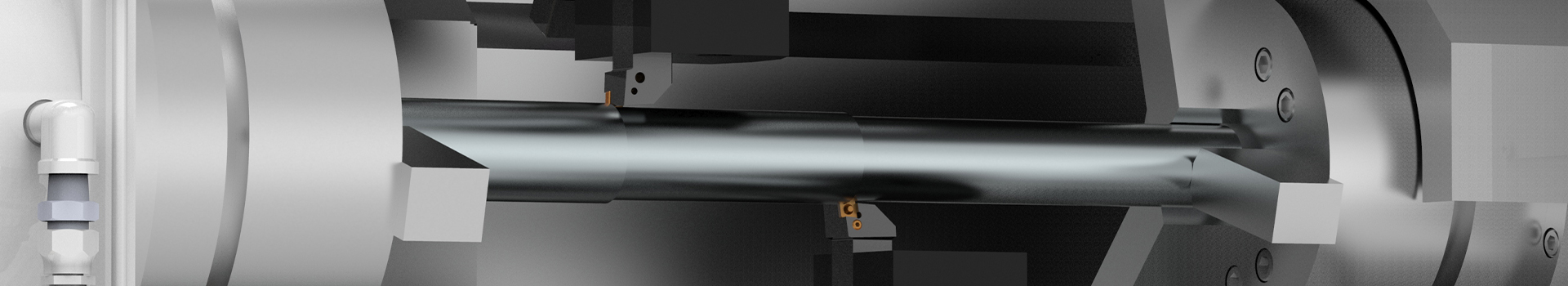

Stability :

Spindle thermal equilibrium experiment ,The relative temperature of spindle is not higher than 20°C. The spindle adopts fully enclosed structure and the vacuum drainage protection device to prevent foreign bodies penetration.

-

Speciality :

High precision, high rigidity, high stability, high efficiency.

Low speed and high torque, high output efficiency.

Compact structure, small size, light weight, fast acceleration and deceleration.

Low vibration, low noise, good balance, good thermal characteristics. -

Accuracy:

Under constant temperature and humidity environment, the spindle is finished with one clamping on the Switzerland Klingberg universal grinding machine.

Strict spindle assembly process, using professional measuring instruments to quantify the spindle preload, to ensure the consistency of the spindle preload, This ensures the accuracy of the spindle and reduces the influence of human factors. -

Capability:

Spindle driven by built-in motor directly, realize "zero transmission". Compact design, light weight, low vibration, low thermal deformation. With characteristics of high torque by low speed and high speed. High precision on both dynamic and static, and high stability.

-

Rigidity:

The front bearing adopts high precision conical double roller bearing & ball bearing and row angular contact ball bearing,which can bear a greater axial load ,to realize heavy cutting and to replace the grinding.

-

Efficiency:

The max spindle speed is 5000rpm. The c-axis of the built in motor spindle adopts the Magnetic grid encoder of Germany Heidenhain. It is locked and brake in the whole cycle, and the acceleration and deceleration are fast.

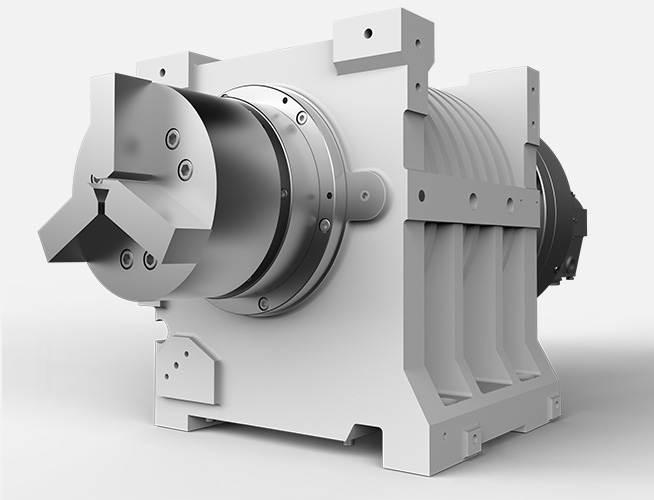

Spindle

Spindle max. torque

Dynamic balance accuracy

Spindle runout

Spindle end runout(300mm)

Spindle root runout

Spindle

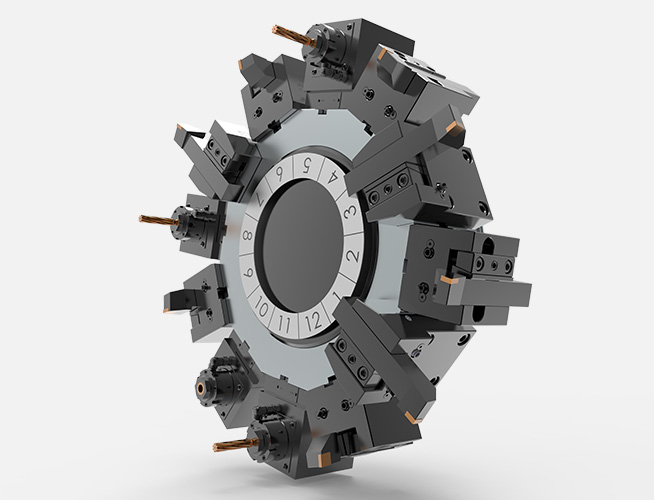

Turret

Locking force

Turret indexing accuracy

Turret indexing accuracy

Indexing time

Turret

-

Rigidity:

The toothed disk is tightly locked by hydraulic force to ensure that the 7Mpa high pressure cooling water still maintains enough tension when passing through the turret.

The tooth disc is made of heat-treated chromium-molybdenum steel with high wear resistance, high hardness,and strong impact resistance. -

Live turret:

The live turret adopts BMT interface. Using four key positioning and bolt fastening, positioning reliable with high precision, rigidity greatly enhanced.

The milling axis adopts 5.5KW motor with maximum torque of 70Nm and maximum speed of 5000rpm. -

Stability:

Turret index without lifting, reduce the tool change movement, avoid scraps & coolant entering inside of the turret to influence the positioning accuracy.

Servo motor direct drive, greatly simplify the transmission structure and control link, improve the reliability of the turret. -

Efficiency:

Fast indexing, adjacent tool position change time 0.15-0.25s.

Intelligent shortest two-way tool change path, and the tool is changed at the same time as the tool returns. High speed feed, reduce non - cutting time. -

Accuracy:

It adopts the basic structure with servo motor indexing, arc gear tooth positioning, hydraulic locking. High indexing accuracy which the turret repeated positioning accuracy is ±0.001mm.

-

Capability:

Can meet the demand of 70kg high pressure water chip breaking, to eliminate the processing process of the iron winding effect, reduce the temperature during processing, prolong the service life of the cutter. It is well-suited for applications in automatic manufacturing.

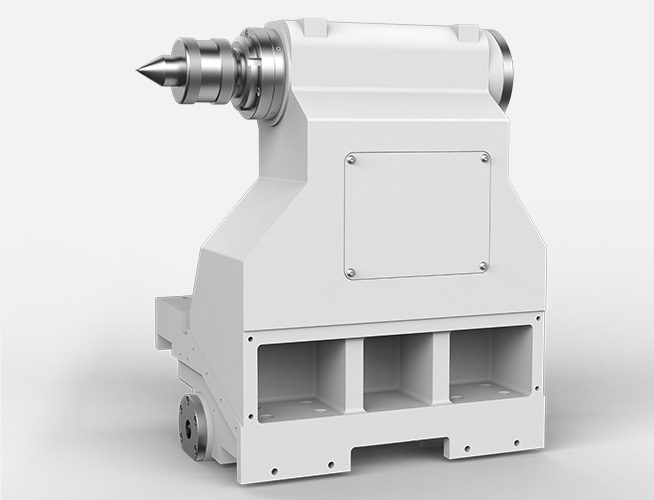

Tailstock

Thrust range

Max. speed

Min. speed

Cone taper

Tailstock

-

Accuracy:

Servo tailstock is supported by linear guideway, and designed and manufactured according to the second Z axis, can be moved to any position, the geometric accuracy is constant, and the parallelism with Z axis 0.01mm.

Servo tailstock similar to sub-spindle design, built-in dead center structure,Five sets of high precision bearings are used to support the tailstock center, the rotation accuracy of tailstock reaches 0.003mm. -

Speciality :

The moving distance and thrust can be set arbitrarily in the program. The machining efficiency and precision can be greatly improved, and it is suitable for automatic machining of long axis parts.

-

Stability:

Servo tailstock adopts solid integral design, servo motor direct drive, drive motor placed outside the processing area, complete protection. It can provide higher stability when processing long parts in the top batch.

-

Efficiency:

The programmable servo tailstock moves to 50mm away from the workpiece at a high speed of 8m/min and is positioned at a low speed of 1.2m/min. It can retreat to any position set within the stroke at a high speed of 8m/min.

-

Rigidity:

Tailstock is supported by wide spaced linear guideway with high precision rotary sleeve structure. It can withstand strong thrust and has high rigidity.

-

Capability:

Programmable servo tailstock with servo motor direct drive, can choose M.T.4 built-in dead center, to ensure the accuracy and greatly reduce the cost of use.

English

English