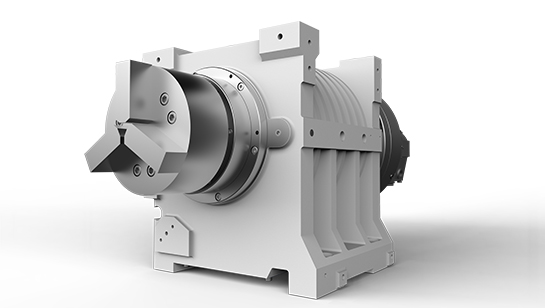

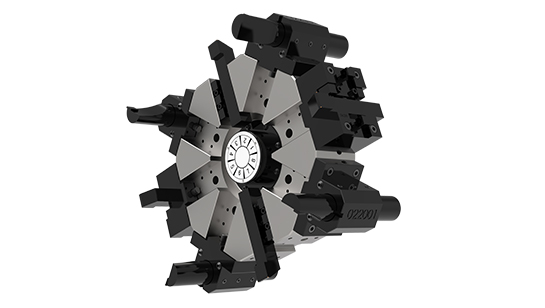

High precision & rigidity mechanical spindle

•High precision and high rigidity spindle structure

• High precision double-side dynamic balance struture

• Quantification measurement of preload

• Spindle thermal equilibrium experiment

• Dynamic precision test

English

English